Balancing cable for elevators

Threaded rod M16

Cable diameter 10 mm

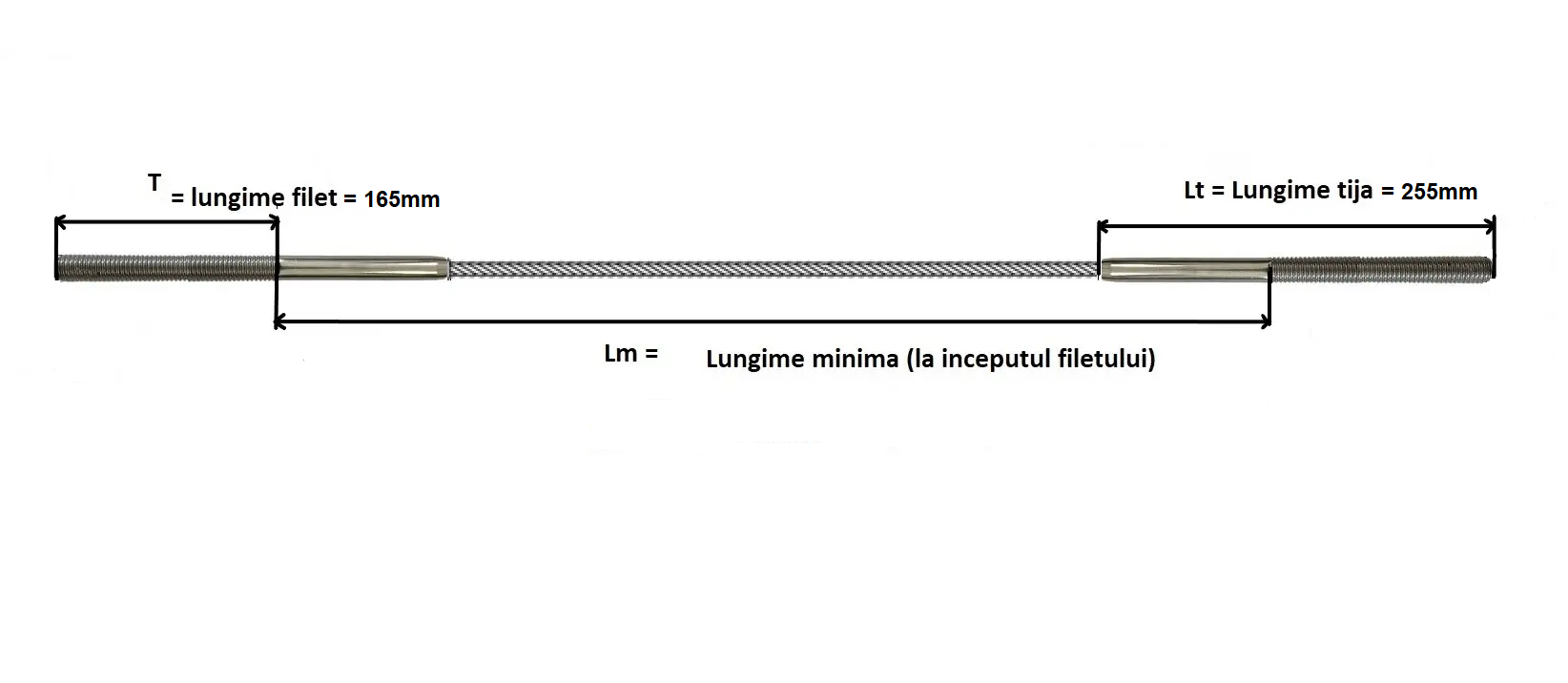

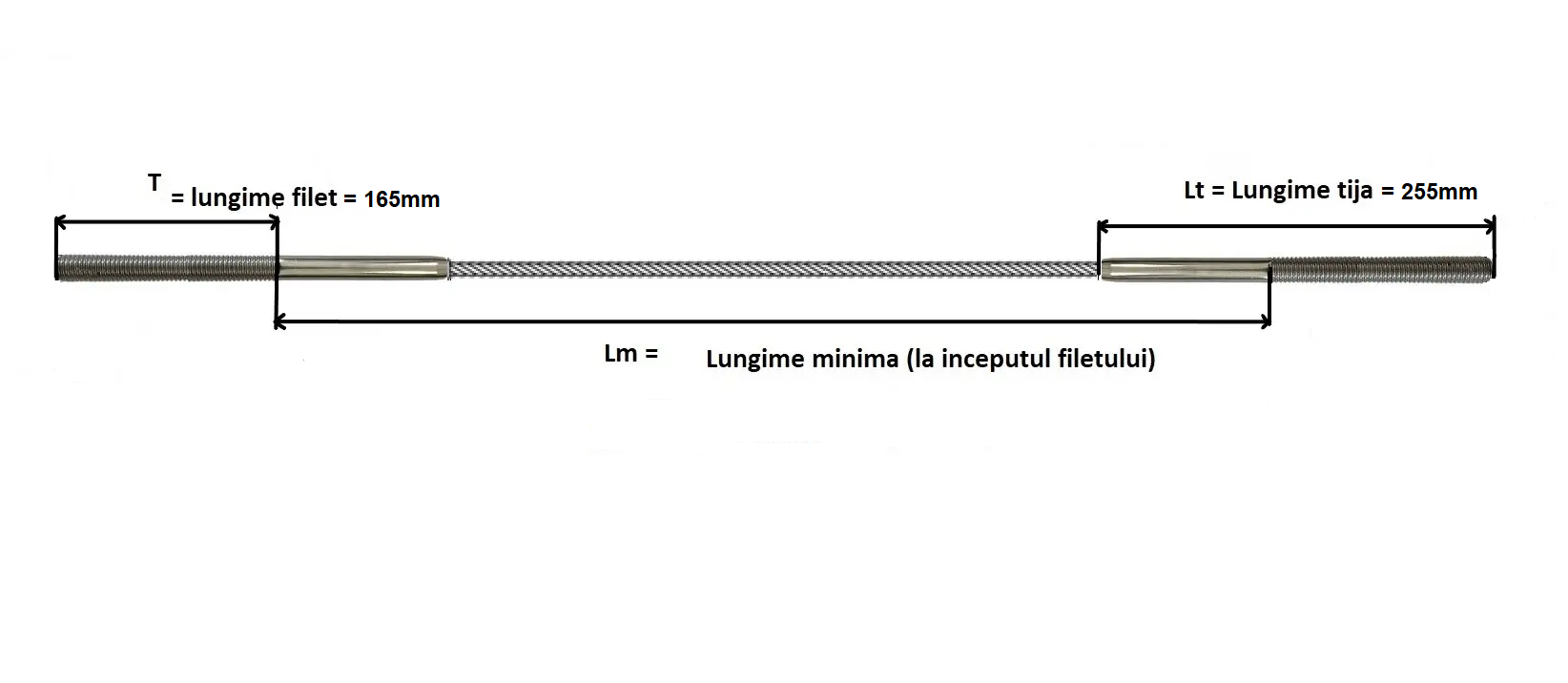

For ordering please provide the following details: Lm – (Distance between rod threads)

We supply balancing cables for any lift model. There are many models of elevators, we can supply balancing cables for any. We use only the highest quality cables.

Important information for offering customized balancing cables :

- Cable length and diameter. The length of the cable must match the model of the lift and not be too short or it will damage the lift. The diameter of the cable must match the pulleys or it will damage the pulleys / jump off the pulleys.

- Threaded rod dimensions. We need the thread type of the rod (usually M16, M12, M18 and M14). The total length of the threaded rod and the length of the threaded section of the rod are also required. For example 210 mm long rod with a 150 mm long thread.

Safety first: Replace car lift cables at the first sign of wear

All wire ropes generally wear from both inside and outside. Interior wear is much less significant. It is caused by the cables being pulled over pulleys or cable wheels. This wear is caused by what is called pinching and can appear on internal threads with an almost wavy appearance.

External cable wear is much more obvious and is essentially abrasive wear. Abrasive wear is the result of metal that is easily worn away or removed over time. This appears on the strands of each thread with a flattening of the thread appearance. As the yarn flattens, the material is lost. As the resistance of the cable continues to decrease, the cable becomes weaker. In addition, almost everyone has at some point seen a rope unfurled. This is a condition where unravelled, worn or separated wires become obvious. If this is observed to occur on any wire rope assembly, immediately discontinue use of the equipment with this type of worn cable. Replace the cable as well as the pulleys or wheels immediately.

Importance of Monthly Inspection: Accident Prevention

As a rule, if you own a car lift or anything else that uses wire ropes, you should perform at least a monthly visual inspection of the ropes and pulleys or wheels. This is particularly important if your equipment. cable is frequently used. If you start to notice that the small round wires that make up each cable assembly start to flatten and then even flatter, it’s time to consider replacing the affected cables. Most cables on car lifts or indeed any equipment, including winches, are easy to replace and the cost is relatively minimal.